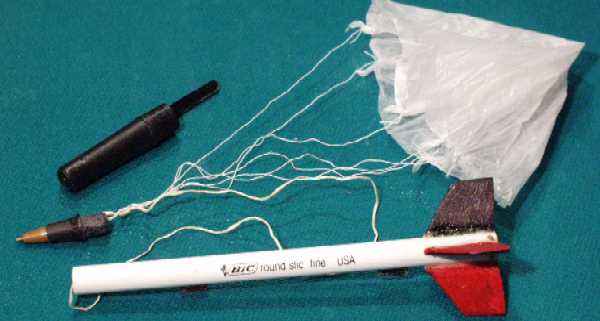

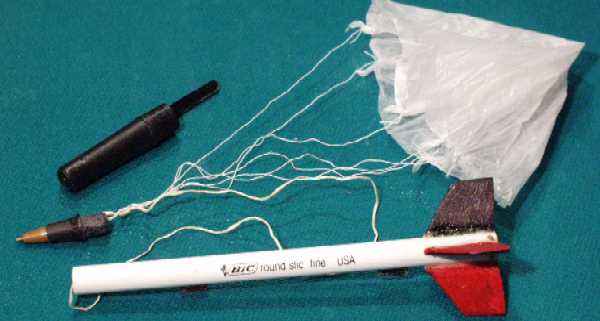

This is a fun little rocket that uses the tiny Quest MicroMaxx motors to loft a Bic(R) pen over 50' in the air and land by Parachute.

"Excuse me sir, but is that a rocket in your pocket?"

This is a fun little rocket that uses the tiny Quest MicroMaxx motors

to loft a Bic(R) pen over 50' in the air and land

by Parachute.

Design

History:

I wanted to design my own MicroMaxx powered rocket but couldn't find

a good material to use for a body tube. I was just getting ready

to roll my own tubes when I noticed that the pen I was holding was about

the right size. This particular brand of pen, the Bic(R)

"Round Stic(R)" has a 5mm inner diameter, and is a

perfect fit for the MicroMaxx motors. It is a bit heavy but is very

strong. As an added bonus, the other parts of the pen supply the

majority of the building materials for the rest of the rocket.

This rocket was designed and built in one evening and flown two days later.

The fin design was just off the top of my head and seemed like a good shape for maximum strength given the thin balsa. It is similar to a WAC Corporal shape although I chose to use four fins instead of the WAC's three. Later I realized that the rocket looked a lot like the HV ARCAS sounding rocket so I renamed this design the Bic(R) ARCAS.

It's first flight was on 10/22/00 with near-perfect results and great chute deployment but the sewing-thread shock cord failed.

The next flight, with new and improved kevlar shock cord, was at the

Blaine, MN MASA

launch on 10/28/00 with perfect launch, flight, deployment, and recovery.

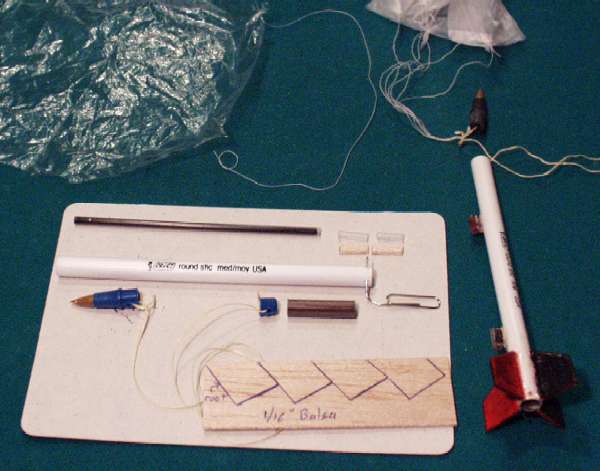

Parts: (click image

for closeup)

Tools/Supplies:

1. Disassemble pen:

a. Twist off tip w/attached ink tube (might

need pliars)

b. Carefully use fingernails or pocket knife

to extract end plug

(If it

won't come off, push it out with a stiff wire from the other end, or, in

stubborn cases,

cut off the last 1/8" of white tube and the end plug will come with it.)

This will be used

in step 5 to construct the motor thrust ring and shock cord attachment

poing.

c. Separate beige ball tip w/attached ink

tube from the colored cone-shaped grip

2. Nose cone:

a. Shorten the shoulder of the conical grip so that

only 3/8" of shoulder remains

(this will give more room for

the chute and make the nose cone eject more easily).

Cut it using a sharp razor knife

by rolling the cone under the knife against a table top (protected by cardboard!).

Save the remaining ring for use

as the motor thrust ring in step 5 if the end plug was not salvagable from

step 1.

b. Note: this step can be messy: Cut off

the ink tube from the tip, leaving about 1/4" so the pen still has some

ink left to write with.

(Yes, this will remain a

functional pen to use for filling out your flight cards!)

c. Plug end of ink tube that is still attached to

the tip with a spike of tissue and soak the tissue with CA glue.

Spray it with CA accellerator/kicker

if you have some. This should keep it from leaking.

d. Cut off and save the clear part of the remaining

ink tube and carefully discard the ink-filled portion.

e. Drill small 1/16" hole in middle of shoulder

of cone using knife tip or drill bit.

f. Carve small groove from hole to end of shoulder

so shock cord will not be pinched.

g. File or sand shoulder of cone until it EASILY

slides in and out of body tube

h. Reinstall the pen tip into the grip.

3. Mark body tube for fins and launch lugs:

a. Mark the fin alignment lines on the body tube.

1. Hold the pen so you are looking at

the aft end. Use a pencil to mark

three equally spaced

120 degree marks on the end edge of the body tube.

2. Lay the tube on a flat table, lay

a pencil on the table perpendicular to the

body tube.

3. Rotate the body tube until an alignment

mark lines up with the pencil tip

4. Slide the pencil on along the aft

2" of the body tube to make the fin

alignment line.

5. Rotate the body tube 120deg and make

another line. repeat for 3rd fin.

b. Using the same technique, mark the launch lug

attachment point line on the body

tube between two fin

lines. this line should extend from the aft end of the

tube to a bit forward

of the mid-point.

4. Build motor retainer clip:

a. Use tip of razor knife, or small drill

bit to make two 1/32" holes each 1/16"

from the aft end of

the body tube and spaced 90 degrees apart, on opposite

sides of a fin line,

opposite of launch lug.

b. Cut a 3/4" piece of normal paper clip wire,

bend the last 1/4" up into an L shape

c. Holding the clip by the short leg of the

L, insert the long leg through the two

holes. It may

take some wiggling to get the holes angled so the clip will

pass between them.

The fit should be firm enough so that the clip will not

fall out on its own,

yet can be inserted and removed fairly easily.

d. Make sure the wire is far enough off to

the side so it will not cross the nozzel

area of the motor.

If it is too close, try again on another part of the tube.

The wire only needs

to cover a small area of the motor in order to prevent the

ejection charge from

blowing the motor out of the rocket.

e. Remove retainer wire for next step.

5. Build and install motor thrust ring/shock cord attachment

ring:

a. Cut a 1/4" cylindrical section from the

pen end plug, discard flat part of the plug.

(If unable to

get a good piece, use the remainder cut from the nose cone in step 2)

b. Make 1/16" hole in side of ring

c. Make small groove from hole to one edge

of ring

d. Insert Kevlar thread into hole and tie

securely (bowline or square knott) leaving

a 1/4" loop so the

knot will not interfere with fit of ring.

e. Insert ring into forward end of body tube

and push all the way down (using unbent large

paper clip or long

dowel) until it is approx 1/2" from AFT end of body tube.

f. Insert spent motor into aft end of tube

and push against a flat table, then with

a tool or another

spent motor until engine is recessed 1/8" from aft end of

body just clearing

the motor retainer clip holes.

g. Insert motor retainer clip

h. Use wire or dowel inserted through top

of tube to push motor retainer ring to

check that it is firmly

against motor so that motor is lightly pusing on motor

retainer clip.

There is no need to glue the ring in place.

i. Remove motor retainer clip and use wire

to push the spent motor out of the body,

without disturbing

the thrust ring, then replace the clip.

6. Launch lugs:

a. Cut two 1/4" pieces from the clear part

of the ink tube saved from step 2d.

b. Make launch lug stand-offs from balsa.

Approx 1/8" wide by 1/4" long. These

are necessary so the

rocket motor will be centered over the ignitor on the

MicroMaxx launch pad.

Some experimentation may be necessary to get the correct

stand-off width.

c. Sand a stripe down the side of each launch

lug tube to help adhesive to stick

d. Use CA glue to glue the balsa standoffs

to the tubes. lay on a piece of

wax-paper on a flat

table so lug will stay parallel with stand-off. Try not

to get CA on your

fingers.

e. Sand two 1/4" long stripe segments of the

launch lug alignment line on the side

of the pen tube. One

at the mid point, and one 1/2" up from the aft end.

f. Use CA glue to glue lugs/standoffs to body

tube. After 30 seconds, try sliding the MicroMaxx

launch rod through

the lugs to verify alignment. If they are not straight, just break

one off

and try again.

7. Fins:

a. Make fin pattern: 7/8" long at root, 5/8" along

the trailing edge, and 1/2" at tip. Use pattern to

layout fins

on 1/16" thick balsa (or cardboard) sheet per above photo. Wood grain

should

be parallel

with the swept leading edge of the fin for maximum strength.

b. Cut out fins with a razor knife. Sand leading,

trailing, and outboard edges to a

rounded or pointed

shape. Sand root edges flat.

c. Sand body tube adjacent to fin alignment lines

so CA glue will stick

d. Apply CA to one fin root edge and press to body

tube so trailing edge is even

with end of tube (use

alignment mark on end of tube and alignment line extending

up body to ensure

alignment. Hold for 20 seconds for CA to set. Wait for a

minute or two before

proceding to the other fins.

e. After all fins are applied, add fin fillets with

epoxy or CA glue mixed with

baking powder or aluminum

oxide powder. I just used medium CA and sprayed

some accellerator

to make an acceptable fillet.

f. Magic markers work great for "painting" the balsa

fins. Paint alternating colors

on opposite sides

of the fins so you can check if the rocket spins during climb

(it shouldn't if the

fins are straight). Note: CA Accellerator will make the

marker ink run.

8. Parachute:

a. Cut 5" diameter hexagonal chute pattern

from paper and tape to plastic bag

material. An

alternate method is to fold a piece of plastic in half, then in

thirds and make one

cut 2.5" from apex.

b. Cut out chute

c. Cut 3 three 12" shroud lines from strong

thread

d. Attach shroud lines to chute. Theory:

tape would be too stiff for such a

small chute so I just tie the line directly to the corners of the plastic.

This has an unintended benefit of causing the chute to be more hemi-spherical

when open.

1. tie a slipknott (or even

simple overhand) close to end of shroud line

2. pinching a corner of

the chute to make a little 1/4" spike

3. slide slip knott over

spike and pull tight (if used an overhand knott in step 1, then

tie a second overhand to form a square knott)

4. attach other end of shroud

line to adjacent corner using same method.

5. repeat for other two

lines

e. Put finger through the three shroud line

loops and pull on the apex of the chute

so all lines are taught

and straight. Then tie an overhand knott in the

end of the combined

shroud lines to form a 1/2" loop.

f. Tie shock cord to nose cone using bowline

or square knott leaving 1/2" diameter

loop so knott does

not get pinched along side of nosecone and to provide a

mounting location

for the chute

g. Attach chute to shock cord by feeding the

shroud line loop through the

shockcord/nosecone

attachment loop, then feed the chute through its own shroud

line loop, gently

pull tight while ensuring all lines are straight.

Stability testing:

Before launching this rocket, make sure that it will be stable

so it doesn't fly into people.

This design has been well tested and if the instructions are

followed exactly it will be stable.

Here's the process to check stability if you've made any alterations

to the design, or just to be sure:

1. Load engine and pack chute according to "Preparation

for Launch" instructions below

2. Find the Center of Gravity (cg) point of the rocket

by balancing it on a pencil or

other thin object.

Mark this point on the body tube with a pencil.

3. Tie a 6' piece of string to the rocket at the cg point

and secure it with a piece

of tape.

4. Twirl the string and rocket over your head and verify

that it flies "pointy end

first". Purposely

try to start swinging with the rocket pointed backwards or

sideways and verify that

it quickly rotates to a nose-first attitude.

5. If the rocket is not stable, it will require larger

fins, or fins angled further

aft. There is not

a convinient way to add nose weight to this type of design.

(although you could try

making a nosecone from the pen cap, which would add

weight to the nose but hurt

performance.

Preparation for Launch:

1. Load engine

a. Remove engine retainer clip

b. Install MicroMaxx motor (verifying it is

nozel end down), until recessed past retainer clip holes.

c. Reinstall engine retainer clip

2. Insert recovery protection wadding. two pea-sized balls

of cellulose or Estes

tissue. Use straightened

large paper clip as a ram-rod but do not push all the

way into the motor, just until

wadding contacts motor thrust ring.

3. Pack chute (Note: do this immediately prior to launch.

A chute packed for several

hours may not open as reliably):

Theory: It is very difficult to pack a large chute

into a small tube and have it

open reliably. The technique used here depends

on the chute being constructed of

a material that will not stick to itself when tightly

compressed (which most

plastics do). Another problem can arise with

a very lightweight rocket not

developing enough descent rate to cause the chute

to inflate. This packing

technique uses the force of the ejection (which

is disproportionately strong for

MicroMaxx motors) to blow the nosecone, shock cord,

and shoud lines out first so

they are stretched out. The canopy is then

blasted out mouth- first so it is

forcefully inflated as it exits the body tube. This

technique has worked flawlessly,

resulting in instant openings.

a. Talc both sides of chute

b. "Flake" (the skydiving term) individual

pannels of chute so it is stretched out

with all lines taut

in center and the material neatly arranged.

c. Fold peak 1" of chute back on itself so

the chute will be short enough to fit

the body tube.

d. While keeping taut, gently sqeeze sides

of chute into a thin cylinder shape.

Do not fold

or roll, just sqeeze.

e. Insert part of shock cord into tube, leaving

enough outside so it is even with

the chute lines and

chute.

f. Insert chute into tube, apex/peak first,

gently sliding it in. Do not force or

cause chute to kink.

Periodically tug on the lines to ensure that the chute

is able to slide back

out easily.

g. Insert a pea sized bit of wadding and use

straightened paperclip to push chute

down far enough to

leave room for lines and nose cone.

h. Make 3/4" S-folds in the lines and shock

cord together between thumb and finger,

then slide into tube.

Insert a small piece of wadding to keep them from falling

out. This is

difficult, especially since Kevlar shock cord is springy.

i. Insert nose cone, making sure to keep from

pinching lines. Check that nosecone

easily slides back

out.

j. Install cap on pen to hold nosecone in

place until ready to launch. (cap will be

removed once rocket

is positioned on the pad)

4. Place rocket on pad:

a. Ensure that safety key is removed from

launch controller and install new

ignitor on MicroMaxx

pad.

b. Place over launch rod on MicroMaxx pad.

c. Remove pen cap

d. Ensure that ignitor slides up into engine

nozel without contacting the motor

retainer clip, which

could short out the ignitor

5. Launch

a. Check that area is clear of people/pets

b. Insert launch key, check for audible continuity

tone

c. 5 4 3 2 1 Launch

d. Rocket will climb about 50-100' then eject

the nosecone and parachute. Because

of the way the chute

is packed, it should open immediately during the ejection

process.

e. Recover the rocket. Note, the engine and

retainer clip may be hot.

f. After allowing 1 minute to cool, remove

the engine retainer clip and insert

the staightened paper

clip from the top end to push the spent motor casing out

of the rocket.

6. Store:

a. Store rocket with chute unpacked and spent

motor removed

b. Clean any exhaust or ejection residue from

the inside of the body tube using a

Q-tip and rubbing

alcohol.

c. Wrap the rocket and chute up in a paper

towel and store inside of a section of

cardboard paper towel

tube or small box.

Build more with different designs. Make sure to test them for stability using the twirling method before launching a new design.

Future Plans:

This project was so successful that I plan to develop other designs

around this concept.

1. Bic(R) Corporal

2. Bic(R) Mercury Redstone

3. Bic(R) Saturn IB (with clustered motors)

4. Bic(R) Saturn V (with clustered motors)

5. Bic(R) Ariane (with drop-off

boosters)

"Bic" and "Round Stic" are registered trademarks of the MM Bic Corporation, Milford, CT. Bic Corporation does not own or market these rockets, their name is used purely to accent the source of some of the rocket's components.

Designs copyright (c) 2000 by Jeffrey P. Hove, all rights reserved. Non-commercial use granted provided credit is given and this web page is linked to any on-line display of rockets derived from these techniques. I reserve exclusive rights to negotiate with Bic Corporation regarding advertising use of the Bic rocket idea.

Back to Jeff's Rockets Page

Back to Jeff's Home Page

My wife Luda's real estate site, www.ludasrealestate.com